🎵 Introduction: The Comeback of a Classic Format

Vinyl records are back—and stronger than ever. In an age dominated by digital music, the warmth and tangibility of vinyl continue to captivate listeners across generations. But how are these treasured discs actually made?

This blog walks you through the entire vinyl pressing process, showcasing how sound becomes physical—from the recording booth to the record store shelf.

🔧 Step-by-Step: How Vinyl Records Are Made

1. Mastering the Music

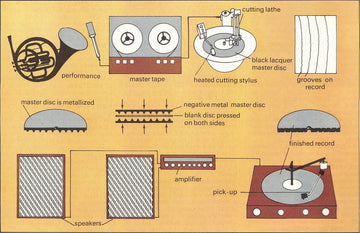

The journey begins with audio mastering. Engineers tweak the mix to suit vinyl’s analog nature—compressing dynamic range, reducing sibilance, and preparing the sound for physical grooves.

2. Cutting the Lacquer Disc

Using a specialized lathe, the audio is etched onto a lacquer disc. This disc is fragile but critical—it captures the music as spiral grooves that can be read by a turntable needle.

3. Creating Metal Stampers

The lacquer is coated with silver and submerged in a nickel bath to create a negative mold called the father. This is used to make a mother (positive), which in turn produces the final stamper used for pressing records.

4. Pressing the Vinyl

Vinyl pellets are melted into a “biscuit” and placed between two stampers inside a hydraulic press. The machine flattens the biscuit into a grooved disc while embedding the music into the vinyl under heat and pressure.

5. Trimming and Cooling

The newly pressed disc is cooled to retain its shape. Extra vinyl around the edges is trimmed to create a clean, circular record.

6. Quality Control

Before full-scale production begins, test pressings are reviewed for defects. Pressings must be clear, well-centered, and free of noise, ensuring every listener gets the perfect playback experience.

7. Final Packaging

Once approved, the records are sleeved, jacketed, shrink-wrapped, and shipped off to music fans worldwide. Many come with liner notes, artwork, or even download codes.

🎬 Bonus: Watch Vinyl Come to Life

Curious to see it all in action? Watch this insider video from Third Man Records:

👉 How Vinyl Records Are Made | WIRED

🔍 Why This Process Still Matters

Even with streaming at our fingertips, vinyl remains the gold standard for musical richness. Every groove is a testament to analog craftsmanship—something no MP3 can replicate. Plus, for artists, pressing music on vinyl remains a bold and tangible statement.

📚 FAQs – How Vinyl Is Made

1. What materials are used to make vinyl records?

Vinyl records are made from polyvinyl chloride (PVC), which is durable and flexible enough to hold microscopic grooves.

2. How long does it take to press a record?

On average, pressing one record takes 30–40 seconds, not including mastering, test pressing, and packaging.

3. What is the difference between lacquer and DMM cutting?

Lacquer cutting uses a soft lacquer disc, while DMM (Direct Metal Mastering) cuts directly onto a metal disc for more precision.

4. Can I press my own record?

Yes! Many boutique pressing plants offer custom pressings for indie artists and collectors.

5. Why do test pressings matter?

They ensure sound quality and help detect physical flaws before mass production begins.

6. Is vinyl better than digital audio?

Vinyl offers a warmer, more immersive experience for many listeners, though digital is more convenient. It’s all about personal preference!

📌 Conclusion: The Magic Behind the Music

Vinyl pressing is more than manufacturing—it's a blend of engineering and artistry that connects us physically with sound. Whether you're a collector or a curious newbie, understanding this journey adds new depth to your next spin on the turntable.